+86 18118016589

lxfyy2003@gmail.com

| Material | Tungsten steel/carbide |

| Coating | DLC colorful |

| Hrc | 56° |

| Flute | 3 |

| OEM & ODM | OK |

| Suitable for | aluminum |

| Whether to support customization | YES |

Roughing End Mill is mainly used to quickly remove a large amount of material from the workpiece during the metal processing process to achieve a predetermined size and shape. It is usually designed with a larger cutting edge for efficient cutting. Roughing cutters generate large cutting forces during processing, but because of their fast cutting speed, they can complete material removal in a short time. They are suitable for the roughing stage, such as mold manufacturing, large parts processing, etc.

The reasonable combination of Roughing End Mill and finishing end mill can effectively improve the efficiency and quality of the entire machining process. Roughing End Mill removes material quickly, laying the foundation for precise machining with the finishing end mill. The finishing end mill further improves the dimensional accuracy and surface finish of the workpiece on the basis of rough milling to meet the final use requirements of the part.

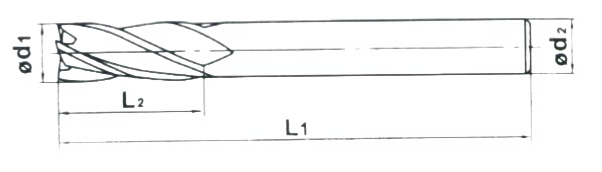

3Flute/HRC56°roughing end mill for aluminum specification table:

| d1 | L2 | d2 | L1 | |

| Specifications | Flute Diameter(mm) | Flute Length(mm) | Shank Diameter(mm) | Overall Length(mm) |

| D4*12*50L*3F | 4 | 12 | 4 | 50 |

| D5*15*50*3F | 5 | 15 | 5 | 50 |

| D6*18*50L*3F | 6 | 18 | 6 | 50 |

| D6*24*75L*3F | 6 | 24 | 6 | 50 |

| D6*30*100L*3F | 6 | 30 | 6 | 75 |

| D8*24*60L*3F | 8 | 24 | 8 | 60 |

| D8*30*75L*3F | 8 | 30 | 8 | 75 |

| D8*35*100L*3F | 8 | 35 | 8 | 100 |

| D10*30*75L*3F | 10 | 30 | 10 | 75 |

| D10*45*100L*3F | 10 | 45 | 10 | 100 |

| D10*60*150L*3F | 10 | 60 | 10 | 150 |

| D12*35*75L*3F | 12 | 35 | 12 | 75 |

| D12*45*100[*3F | 12 | 45 | 12 | 100 |

| D14*45*100L*3F | 14 | 45 | 14 | 100 |

| D16*45*100L*3F | 16 | 45 | 16 | 100 |

| D16*70*150L*3F | 16 | 70 | 16 | 150 |

| D18*45*100L*3F | 18 | 45 | 18 | 100 |

| D20*45*100L*3F | 20 | 45 | 20 | 100 |

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.