Cemented carbides are the most widely used material for milling cutters, thanks to their exceptional combination of hardness, wear resistance, and mechanical strength. Among the various types of cemented carbides, ultrafine-grained cemented carbide (UFCC) and conventional cemented carbide (CCC) are two dominant options in industrial milling applications. The core difference lies in the grain size of tungsten carbide (WC) particles, which directly impacts the cutter’s performance, durability, and suitability for specific milling tasks. This article clarifies the key distinctions between the two materials and their practical implications in milling operations.

Key Differences in Material Properties

1. Grain Size

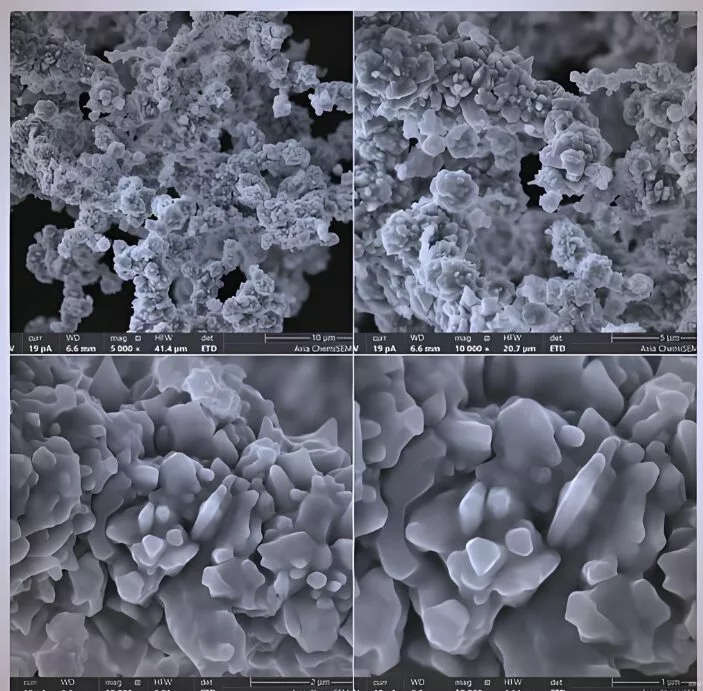

- Conventional Cemented Carbide: WC grain size typically ranges from 1.0 to 5.0 μm (micrometers). Larger grains are formed through standard sintering processes without grain refinement techniques.

- Ultrafine-Grained Cemented Carbide: WC grain size is reduced to 0.2 to 1.0 μm via advanced sintering technologies (e.g., HIP sintering, nanotechnology-aided grain control). The refined grain structure is the defining feature of this material.

2. Hardness & Wear Resistance

- Conventional Cemented Carbide: Moderate hardness (HRA 89–91) and wear resistance. Suitable for general-purpose milling of low-to-medium hardness materials (e.g., carbon steel, cast iron).

- Ultrafine-Grained Cemented Carbide: Significantly higher hardness (HRA 92–94) due to the Hall-Petch effect—finer grains restrict dislocation movement, enhancing material density and resistance to abrasive wear. Ideal for milling high-hardness alloys (e.g., stainless steel, titanium alloys) and high-speed cutting (HSC) applications.

3. Strength & Toughness

- Conventional Cemented Carbide: Higher fracture toughness (10–15 MPa·m¹/²) but lower transverse rupture strength (TRS: 1500–2000 MPa). More resistant to chipping in heavy-load milling but prone to wear in high-speed operations.

- Ultrafine-Grained Cemented Carbide: Improved transverse rupture strength (TRS: 2500–3500 MPa) and balanced toughness (8–12 MPa·m¹/²). The fine-grain structure reduces internal defects, enabling the cutter to withstand higher cutting forces and shock loads without breaking—critical for precision milling and interrupted cutting.

4. Cutting Performance

| Performance Metric | Conventional Cemented Carbide | Ultrafine-Grained Cemented Carbide |

|---|---|---|

| Cutting Speed | Moderate (100–300 m/min for steel) | High (300–600 m/min for steel) |

| Cutting Edge Sharpness | Good for roughing | Excellent for finishing (sharp edge retention) |

| Chip Evacuation | Adequate for low-speed milling | Superior (reduced friction, less chip adhesion) |

| Resistance to Thermal Shock | Moderate | High (stable performance at high temperatures) |

5. Cost

- Conventional Cemented Carbide: Lower production cost (simpler sintering processes, no grain refinement additives). More cost-effective for high-volume, general-purpose milling.

- Ultrafine-Grained Cemented Carbide: Higher cost (advanced sintering equipment, precise grain control). Justified for high-value applications requiring long tool life, precision, or machining of difficult-to-cut materials.

Practical Applications in Milling

Conventional Cemented Carbide Milling Cutters

- Best for roughing operations (e.g., removing large material volumes from carbon steel, gray cast iron).

- Suitable for low-speed, heavy-load milling where toughness is prioritized over wear resistance.

- Ideal for general manufacturing scenarios (e.g., automotive components, construction machinery parts) where cost efficiency is key.

Ultrafine-Grained Cemented Carbide Milling Cutters

- Preferred for finishing and semi-finishing operations (e.g., precision machining of aerospace components, medical devices).

- Excels in milling difficult-to-machine materials (e.g., Inconel, duplex stainless steel, hardened steel > HRC 45).

- Essential for high-speed milling (HSM) and high-efficiency machining (HEM) where tool life and surface quality are critical.

- Suitable for interrupted cutting (e.g., milling castings with irregular surfaces) due to superior strength and shock resistance.

The choice between ultrafine-grained and conventional cemented carbide milling cutters depends on three core factors: material to be machined, milling parameters (speed, feed, depth of cut), and application requirements (precision, tool life, cost). Conventional cemented carbide offers a cost-effective solution for general-purpose milling, while ultrafine-grained cemented carbide delivers superior performance in high-precision, high-speed, or difficult-to-machine scenarios. By understanding these key differences, manufacturers can optimize tool selection, reduce production costs, and enhance machining efficiency.