1. Material: Carbide/0.06UM micro-particle imported tungsten steel

2. Coating: colorful coating/nano bronze

3.HRC: 56°

4.Can accept customization

5.Flute: 4

6. Applicable materials: cast steel, cast iron, copper, stainless steel, alloy steel, mold steel, etc.

7. Applicable machines: CNC machining centers, CNC machine tools, engraving machines, precision engraving machines and other high-speed machines

8. High smoothness and no burrs

9. Lower noise, lower friction and higher speed, not easy to get hot, higher bearing load

10. Chinese manufacturer with 10 years of experience, cheap price

The name dovetail milling cutter sounds very vivid and intuitive. It comes from the shape of the dovetail groove produced by this milling cutter. A dovetail groove is a groove with a specific angle and shape. Its cross-sectional shape is similar to the tail of a swallow, hence its name.

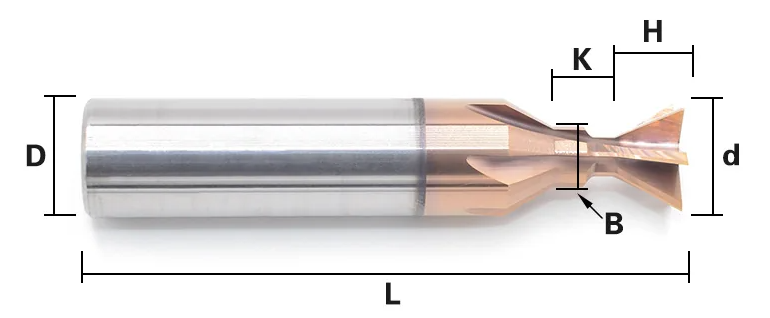

The specific sizes are as shown in the table below. If there are other needs, they can also be customized.

| Degrees | Specification |

| 60° | d2*60°*0.32H*B0.9*4K*D4*50L*4F |

| d3*60°*0.47H*B1.4*6K*D4*50L*4F | |

| d4*60°*0.62H*B1.9*8K*D4*50L*4F | |

| d5*60°*0.79H*B2.3*10K*D6*50L*4F | |

| d6*60°*0.94H*B2.8*10K*D6*50L*4F | |

| d8*60°*1.29H*B3.6*12K*D8*60L*4F | |

| d10*60°*1.61H*B4.5*15K*D10*60L*4F | |

| d12*60°*1.94H*B5.4*18K*D12*60L*4F | |

| 45° | d2*45°*0.55H*B0.9*4K*D4*50L*4F |

| d3*45°*0.80H*B1.4*6K*D4*50L*4F | |

| d4*45°*1.05H*B1.9*8K*D4*50L*4F | |

| d5*45°*1.35H*B2.3*10K*D6*50L*4F | |

| d6*45°*1.60H*B2.8*10K*D6*50L*4F | |

| d8*45°*2.20H*B3.6*12K*D8*60L*4F | |

| d10*45°*2.75H*B4.5*15K*D10*60L*4F | |

| d12*45°*3.30H*B5.4*18K*D12*60*4F | |

| 30° | d2*30°*0.96H*B0.9*4K*D4*50L*4F |

| d3*30°*1.40H*B1.4*6L*D4*50L*4F | |

| d4*30°*1.84H*B1.9*8K*D4*50L*4F | |

| d5*30°*2.37H*B2.3*10K*D6*50L*4F | |

| d6*30°*2.81H*B2.8*10K*dD6*50L*4F | |

| d8*30°*3.86H*B3.6*12K*D8*60L*4F | |

| d10*30°*4.82H*B4.5*15K*D10*60L*4F | |

| d12*30°*5.79H*B5.4*18K*D12*60L*4F |

Types of dovetail slot milling cutter

1、Reamer with cutting edge

Flanged reamer is characterised by a small inclination angle, i.e. the angle of the side is less than 90 degrees, so it is suitable for processing smaller dovetail grooves. In addition, the fluted reamer also has good cutting performance, can also be processed curved shape, very suitable for the needs of the metal processing industry.

2、No-flute reamer

Flagless reamer is characterised by no front angle, only a fine profile. This type of reamer is mainly used to process larger dovetail grooves with higher precision, and is also suitable for beer marking and scribing metal parts.

3、T-type dovetail milling cutter

The T-shaped dovetail milling cutter is characterised by a cutting edge designed in the head of the reamer, which can make the cutting surface more flat during processing, while the U-shaped is designed with a drill bit in the head, which can be more clearly positioned.

4、Plate shaped dovetail cutter

Also known as facing milling cutter, it is a kind of flat cutter, which is mainly suitable for face milling cutting slot and slot milling cutting surface, commonly used in cold drawing processing.

the use of methods

1、Choose the right milling cutter

In the use of dovetail slot milling cutter, first of all, according to the type of metal parts to be processed and size to choose a suitable milling cutter. Different milling cutter applicable machining accuracy, size and material is also different.

2、Preparatory work

Before machining, must ensure that the positioning of the workpiece is accurate and stable, to avoid offset during processing. Also clean up the processing area, keep the worktable flat and clean.

3, adjust the tool

Adjustment of the tool is a very important step before processing, according to the shape of the processed metal parts to adjust the position and angle of the milling cutter. First of all, you need to fix the milling cutter on the milling machine, and then adjust.

4、Machining

After adjusting the tool, you can start processing. In the processing, must keep the position of the workpiece and the tool is stable and appropriate amount of lubricant, appropriate amount of cooling saw blade.

5, check the quality of processed products

After the completion of processing, the need to check the processed products to ensure that their quality meets the requirements. If found defective or unqualified places, need to timely adjust the tool and processing conditions.

In short, the dovetail milling cutter is one of the essential cutting tools in the metal processing and manufacturing industry. Only by selecting the correct tools according to milling requirements can the efficiency of metal processing and the quality of processed products meet the requirements.

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us