Cermet is a heterogeneous composite material composed of a metal or alloy and one or several ceramic phases, of which the latter accounts for about 15% to 85% (volume). At the same time, at the preparation temperature, the metal and ceramic phases The solubility between them is quite small. The TiC(N)-based cemented carbide used to make cermets (TiC(TiN)-WC+Ni(Mo)+Mo2C) for cutting tools is based on TiC (ceramic) (sometimes other carbides and nitrides are added) , carbide materials with Ni, Mo or Co (metal) as binder (usually containing 10%~20% binder).

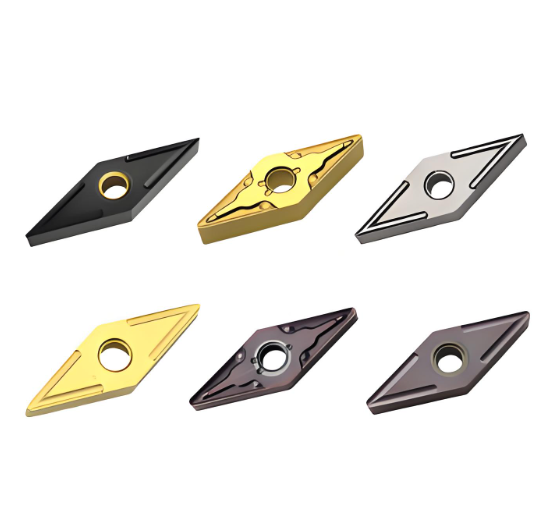

The hardness of TiC(N)-based cemented carbide alloy is very high (90~94HRA), almost reaching the level of ceramics, so it is also called "cermet". (Figure A)In particular, the bonding temperature between TiC(N) and steel is high, so the crater wear resistance is very good. Its biggest advantage is that its material has extremely low affinity with the material to be processed, so it is not easy to cause tool sticking and built-up edge, making the processing surface very smooth and smooth. Its tool life is several times longer than that of WC-based cemented carbide. However, its bending strength and toughness are worse than those of WC-based carbide, and its resistance to plastic deformation and chipping resistance is poor. Therefore, it is mainly used for high-speed finishing or semi-finishing of carbon steel, stainless steel, ductile iron, etc., and is not suitable for heavy cutting. and interrupted cutting. By adding carbides such as WC, TaC, TiN, and TaN, the flexural strength and toughness can reach the level of WC-based cemented carbide.

The characteristics of cermets can be summarized as:

(1) Low density, hardness and thermal hardness are higher than WC-based cemented carbide.

(2) Strong wear resistance and crater wear resistance.

(3) Good chemical stability and antioxidant properties.

(4) The affinity with the workpiece material is small, the friction coefficient against steel is small, and it is not easy to cause sticking and built-up edge.

(5) The thermal expansion coefficient is higher than that of WC-based cemented carbide.

Cermet is a tool material suitable for finishing, which can ensure good dimensional accuracy and surface roughness. Cermets are mainly used in the processing of long-chip materials such as steel, and are currently used to process materials such as cast iron and stainless steel. The key to using cermet tools is to choose the appropriate blade shape, tool tip radius and geometry (an optimized combination of material and geometry). In order to obtain the best productivity and safety, the feed rate should be as large as possible and the amount of back cutting should be as small as possible.