Many mechanical components feature internal bore grooves. Most annular grooves are positioned close to the entrance of the hole, such as snap ring grooves or seal grooves. The most common method for machining internal grooves is radial grooving. Grooving and parting represent a distinct category within turning applications, widely used across various machining scenarios and requiring specialized tools. These tools can, to some extent, be viewed as an extension of conventional turning. The development of machining centers and multi-tasking machines, coupled with the need to process complex asymmetrical components, has also made milling a viable method for creating grooves.

Precautions for tool usage when machining deep, narrow annular grooves within small holes during the turning process: The selection of methods for machining these grooves primarily depends on workpiece characteristics, workpiece material, production quantity, and machine tool parameters, as detailed in the table below.

| Form Of Existence | Explanation | |||

| Mistake |

|

|

1. Poor workpiece surface condition 2. Obvious vibration at the workpiece end 3. Poor chip breaking 4. Insufficient tool life 5. Excessively high cutting zone temperature 6. Excessively high cutting speed 7. Insufficient cutting fluid 8. Inappropriate tool material 9. Excessively high feed rate 10. Oxidation at the cutting edge 11. Insufficient groove shape |

|

|

|

|

|||

| Correct |  |

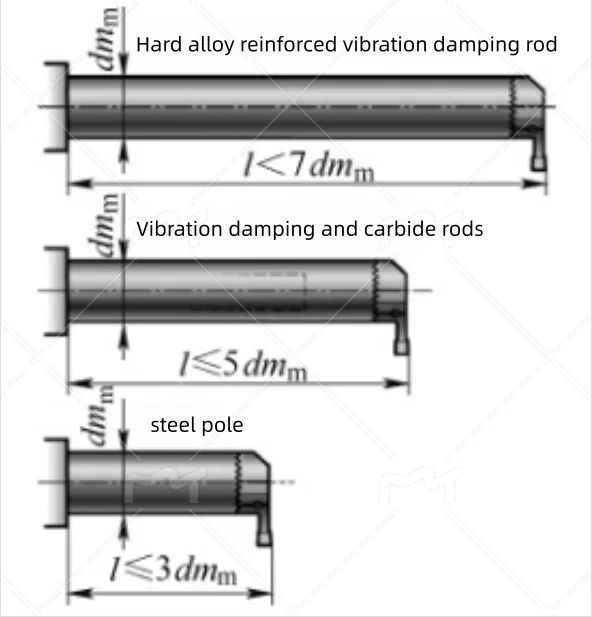

1. When cutting grooves in small holes, use solid carbide or vibration-damping tool holders whenever possible. The overhang length of a steel tool holder should not exceed 3 times the tool diameter; the overhang length of a carbide tool holder should not exceed 5 times the tool diameter; the overhang length of a carbide-reinforced vibration-damping tool holder can reach 7 times the tool diameter.

2.To avoid vibration, choose the lightest cutting groove shape. Using narrower inserts and inserting them several times can also avoid vibration. Finishing should be performed at the end. After turning, use a single insert to machine the groove, starting from the bottom and machining backwards to the front of the hole to achieve optimal chip removal. |

||