1. The higher the strength and hardness of the workpiece material, the more work is consumed during cutting, the more cutting heat is generated, and the higher the cutting temperature is. The greater the thermal conductivity of the workpiece material, the more heat is transmitted through the chips and the workpiece, the faster the cutting temperature drops.

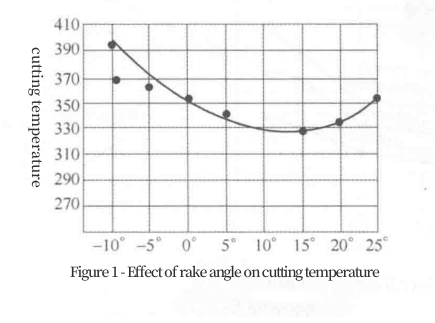

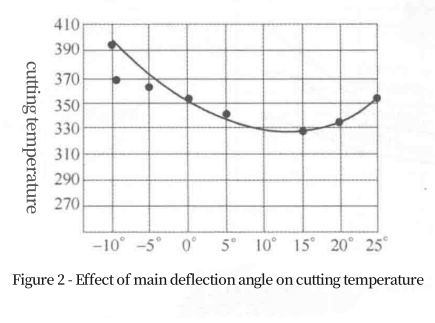

2. Tool geometry parameters increase the front angle, cutting deformation is reduced, less heat generated, cutting temperature reduction; but too large front angle to reduce the volume of heat dissipation, when the front angle is greater than 20 ° ~ 25 °, the front angle of the impact on the cutting temperature is reduced. The main deflection angle decreases, so that the cutting degree increases, the heat dissipation area increases, the cutting temperature decreases, as shown in Figure 1 and Figure 2.

|

|

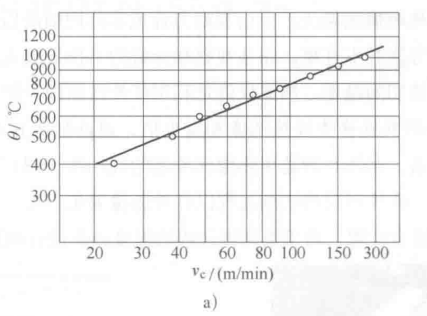

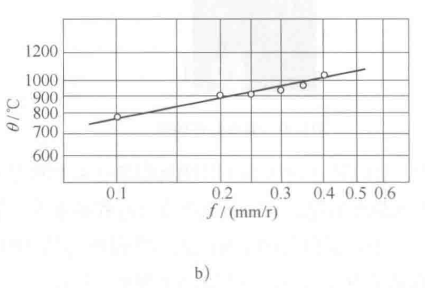

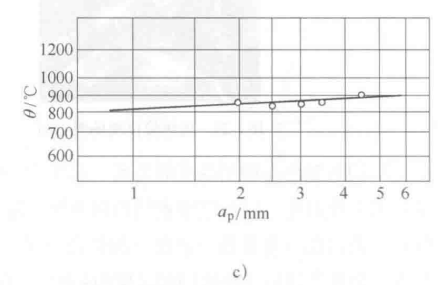

3. Cutting amount on the cutting temperature of the greatest impact of the cutting amount of cutting speed, followed by the amount of feed, and back eating amount of the smallest impact, this is because when the cutting speed ",increase, the amount of metal involved in deformation per unit of time to increase the amount of power consumed to increase, the cutting temperature rises; when / increase, the cut becomes thicker, by the heat taken away by the chip increases, so the cutting temperature rise is not very obvious; when a, increase When a, increase, the heat generated and heat dissipation area increased at the same time, so the impact on the cutting temperature is also small, as shown in Figure a, b, c.

|

|

|

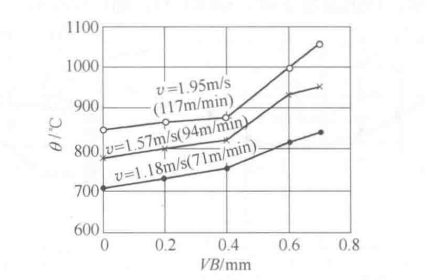

4. Other factors tool after the tool surface loss increased, intensifying the friction between the tool and the workpiece, so that the cutting temperature rises, the higher the cutting speed, tool wear on the cutting temperature of the more significant impact (see Figure 3). Pouring cutting fluid to reduce the cutting temperature to reduce tool wear and improve the quality of the machined surface has an obvious effect. The lubricating effect of cutting fluid can reduce friction and reduce the generation of cutting heat.