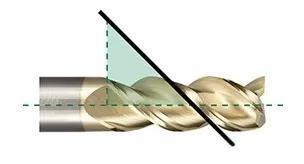

While many factors affect machining outcomes, the helix angle of milling cutters remains a frequently underestimated parameter. Defined as the angle between the tool centerline and a tangent line to the cutting edge, this critical feature directly impacts:

-

Chip evacuation efficiency

-

Surface finish quality

-

Tool lifespan

-

Machining cycle time

Helix Angle Classification

-

Low Helix Angles (<40°)

-

Typical applications: Heavy material removal

-

-

High Helix Angles (>40°)

-

Typical applications: Precision finishing

Milling cutter helix angle

-

Fundamental Principle

As helix angle increases, the engaged cutting edge length decreases. Both extremes (<40° and >40°) present unique trade-offs:

Low Helix Angle Tools (<40°)

✅ Advantages

-

Enhanced Structural Integrity

-

Larger core diameter resists bending deformation

-

-

Workpiece Stability

-

Reduced radial forces minimize workpiece displacement risks

-

-

Aggressive Material Removal

-

Generates larger chips for rapid bulk cutting

-

❌ Disadvantages

-

Suboptimal Surface Finish

-

Chip evacuation challenges cause surface irregularities

-

-

Feed Rate Limitations

-

-

High radial forces necessitate slower feed rates

-

-

High Helix Angle Tools (>40°)

✅ Advantages

-

Superior Cutting Stability

-

Enhanced shearing action reduces vibration (particularly critical for thin-wall machining)

-

-

Effective Chip Management

-

Increased axial forces promote rapid chip removal

-

-

Precision Surface Quality

-

Reduced radial forces enable clean material separation

-

❌ Disadvantages

-

Reduced Cutting Edge Durability

-

Thinner tool geometry increases wear susceptibility

-

-

Deflection Sensitivity

-

Flexible teeth require strict parameter control

-

-

Catastrophic Failure Risks

-

-

Uncontrolled deflection may cause tool breakage

-

-

Key Considerations for Tool Selection

When choosing a milling tool, evaluate:

-

Material properties (hardness, ductility)

-

Operation type (roughing vs. finishing)

-

Machine rigidity (to counteract deflection risks)

-

Chip load requirements (linked to helix angle effects)