In manufacturing, milling and drilling processes are foundational for shaping workpieces into precise components, each tailored to specific surface, cavity, or contour requirements. From creating flat surfaces to machining complex 3D shapes, the right process selection directly impacts efficiency, precision, and tool life. Below is a detailed breakdown of seven key milling and drilling processes, their core characteristics, and how they differ in practical application.

1. Face Milling

Face milling is primarily used to produce flat, smooth surfaces on the top or side of a workpiece. The process relies on the end teeth of the milling cutter to engage with the material, removing material in a controlled manner to achieve the desired flatness.

A critical parameter in face milling is cutter engagement, defined by two key values:

- Radial engagement (ae): Typically small, as the cutter only contacts a portion of the workpiece’s width.

- Axial engagement (ap): Relatively large, allowing for deeper material removal in a single pass while maintaining surface quality.

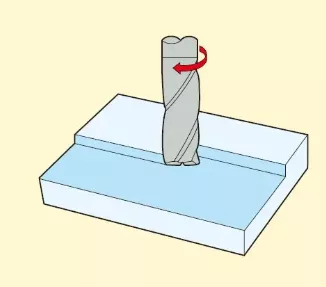

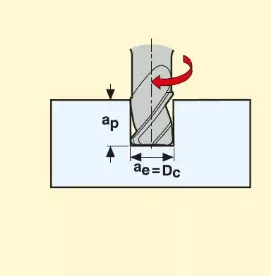

2. Slot Milling

Slot milling is designed to create narrow or wide slots in a workpiece, where the cutter’s diameter is fully engaged with the material. This distinguishes it from other processes where only partial cutter contact occurs.

In slot milling:

- Radial engagement (ae) equals the cutter diameter (D): The full width of the cutter interacts with the workpiece, making it ideal for creating slots matching the cutter’s size.

- Axial engagement (ap): Can be as large as 15 times the cutter diameter (D), depending on the machining strategy (e.g., layered cutting vs. single-pass deep cutting) and tool rigidity.

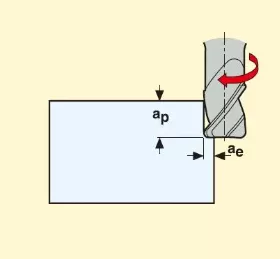

3. Side Milling

Side milling uses the side teeth of the cutter (rather than the end teeth) to machine surfaces, often for creating vertical walls, shoulders, or refining the edges of a workpiece.

Cutter engagement in side milling is characterized by:

- Radial engagement (ae): Large, as the side of the cutter makes substantial contact with the workpiece’s vertical surface.

- Axial engagement (ap): Small, limiting the depth of cut along the Z-axis to ensure stable cutting and prevent tool deflection.

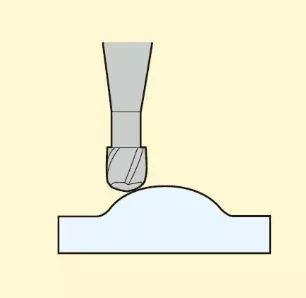

4. Profiling (Contour Milling)

Profiling, or contour milling, is used to machine complex 2D or 3D shapes by following the workpiece’s contour. It typically employs a ball-nose cutter, where the ball-shaped tip engages with the material to create smooth, curved surfaces.

Key engagement features:

- Both radial engagement (ae) and axial engagement (ap) are small: This precise, low-contact cutting ensures the cutter follows the contour accurately, avoiding overcutting and producing high-quality surface finishes—common in mold and die manufacturing.

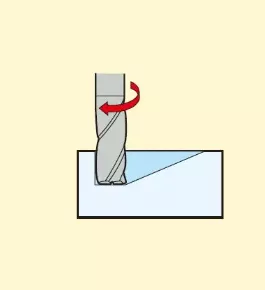

5. Ramp Milling

Ramp milling is a variation of cavity milling where the cutter enters the material at an angle along the Z-axis (rather than straight down). This angled entry reduces sudden cutting forces, minimizing tool wear and improving cutting stability.

It is particularly useful for roughing cavities, as the gradual engagement distributes load evenly across the cutter teeth, preventing chipping or breakage in tough materials like steel or titanium.

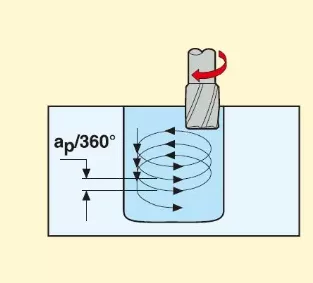

6. Helical Interpolation Ramp Milling

Building on standard ramp milling, helical interpolation ramp milling combines an angled Z-axis descent with a circular motion in the X-Y plane. This creates a helical tool path that allows the cutter to enter the material smoothly while expanding the cavity diameter gradually.

The helical motion eliminates the shock of direct axial entry, making it ideal for machining deep cavities or when using small-diameter cutters that require extra stability. It also reduces tool vibration, leading to longer tool life and better surface quality.

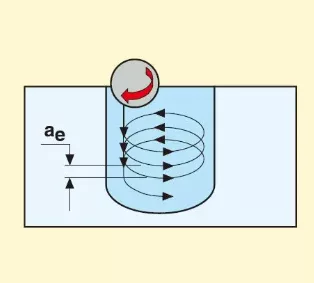

7. Cycloidal Milling

Cycloidal milling reimagines slotting by replacing full-diameter cutter engagement with partial circular motions in the X or Y axis, paired with side milling. Instead of forcing the cutter to engage fully (as in slot milling), it uses a cycloidal path—small, overlapping arcs—to remove material incrementally.

This "slotting-to-side-milling" transformation reduces radial cutting forces significantly, as the cutter only contacts a portion of the material at each arc. It is highly efficient for deep slotting or machining hard materials, as it minimizes tool stress and heat buildup.

Bonus: Complementary Processes

While the seven processes above are core to milling, two additional techniques often work alongside them to address specialized needs:

- Push-Pull Profiling: Used for 3D surface machining, this process involves the cutter following the workpiece’s 3D contour with up-and-down profiling motions. It ensures consistent contact across irregular shapes, making it essential for aerospace or automotive components with complex geometries.

- Plunge Milling: A hybrid of milling and drilling, plunge milling uses axial (Z-axis) drilling motions to create deep slots or cavities. The cutter is fed straight down into the material, making it faster than side milling for deep, narrow features—though it requires high tool rigidity to avoid deflection.

Each of these milling and drilling processes offers unique advantages, from flat surface creation (face milling) to complex 3D contouring (profiling) and efficient deep cavity machining (helical interpolation). By understanding their engagement characteristics and typical applications, manufacturers can select the optimal process to balance precision, speed, and tool longevity.