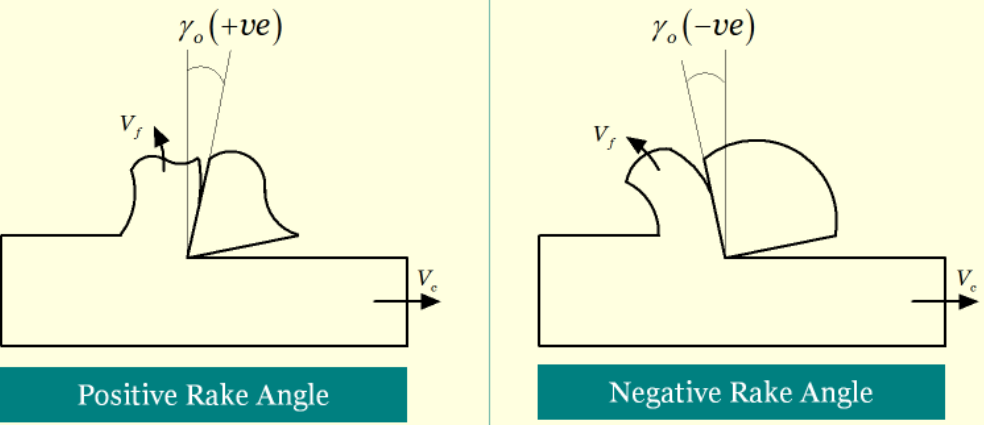

Chip formation can also show whether the most suitable tool is being used. If chip formation is not up to par, the tool geometry may need to be changed to improve the situation. Clearly, the geometry of the cutting tool has a significant impact on chips. Specifically, increasing the rake angle can improve chip formation, but this comes at a cost because the larger the rake angle, the weaker the cutting edge. The rake angle also has a great influence on the value of the shear face angle, which is the angle formed by pure plastic deformation of the workpiece material. Here, the material begins to deform or form chips in front of the cutting edge. Angle varies with material properties and cutting parameters; however, making the shear plane angle more vertical should always be a goal because the steeper the shear plane, the better chip formation will be.

Chip thickness also plays a role here. The more elastic the material, the steeper the shear angle, resulting in thinner chips. Conversely, the harder the material, the flatter the shear angle, which means the thicker chips are formed. All in all, a larger rake angle means a larger shear angle, which means better chips, but balance is key here too. A really sharp cutting edge will produce a lot of chips, but due to the small cross-section of the cutting edge and the weak cutting edge, breakage will occur, so you need to find a relatively suitable angle in the rake angle.