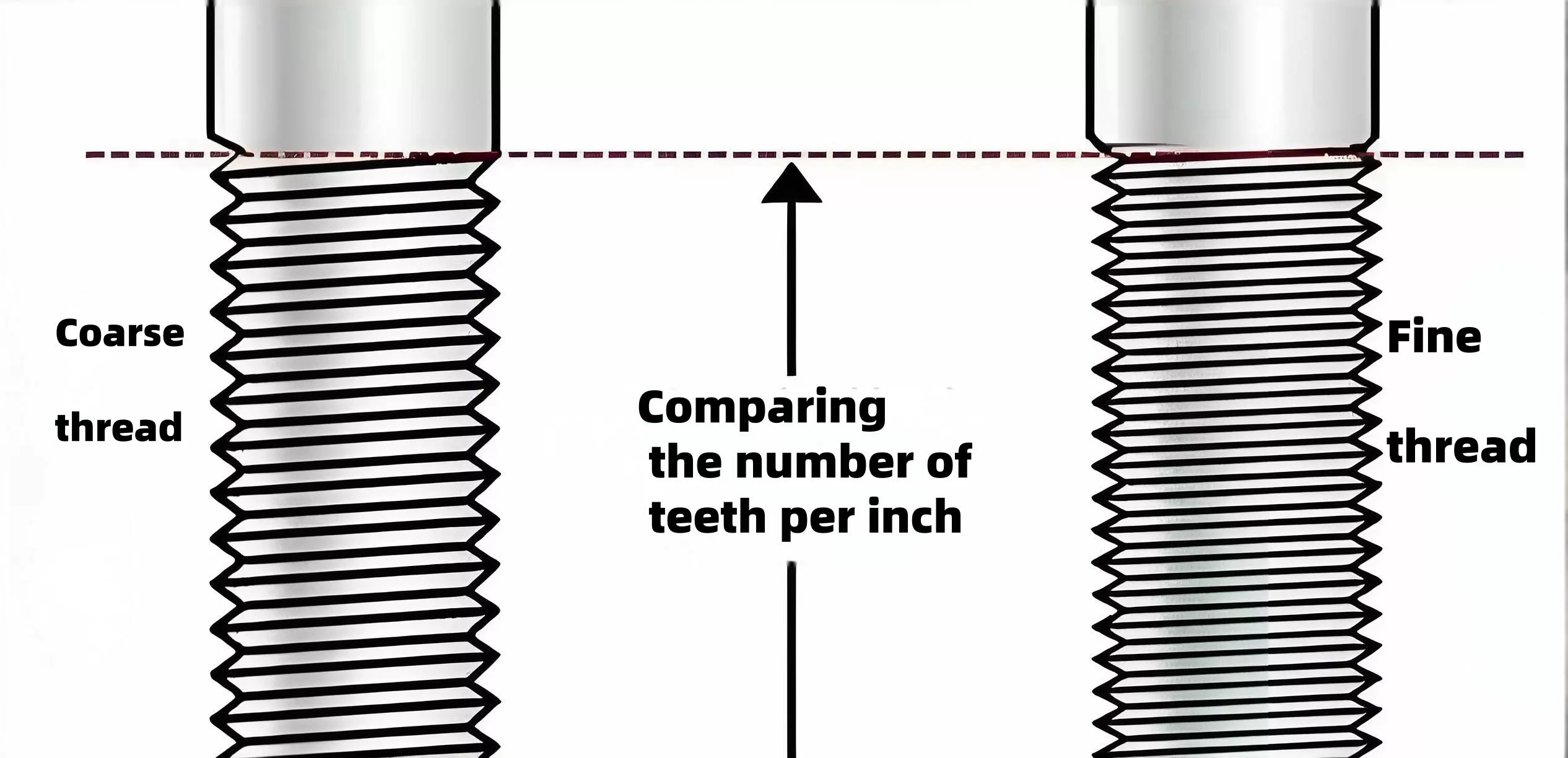

To what degree of precision can a thread be classified as a fine thread? We may define it as follows: coarse threads can be regarded as standard threads, while fine threads are defined in relation to coarse threads. For the same nominal diameter, the number of threads per inch varies, meaning the pitch differs. Coarse threads have a larger pitch, whereas fine threads have a smaller pitch. For instance, between the specifications 1/2-13 and 1/2-20, the former is a coarse thread and the latter a fine thread. Thus, they are designated as 1/2-13 UNC and 1/2-20 UNF, respectively.

Since the same nominal diameter can have two different thread specifications, what are the selection criteria for coarse and fine threads?

Coarse thread

Coarse threads are essentially the standard default. Unless otherwise specified, standard fasteners like stainless steel screws are typically supplied with coarse threads.

Coarse threads are characterized by their high strength, excellent interchangeability, and standardized specifications. As a rule, they should be the preferred choice. In contrast, fine threads have a smaller pitch and a larger helix angle, which results in inferior self-locking performance. In vibrating environments, they often require additional anti-loosing measures, such as lock washers or other self-locking devices. Their advantages, however, include easier assembly and disassembly, wide availability of matching standard parts, and good interchangeability.

Coarse threads do not require the pitch to be specified in their designation. Examples include M8, M12-6H, and M16-7H. They are primarily used for fastening applications.

Fine thread

Fine threads, in contrast to coarse threads, are specified to meet special application requirements that coarse threads cannot satisfy. Fine threads feature a smaller pitch, which gives them distinct advantages: they provide better self-locking and resistance to loosening, and the higher number of threads per unit length enhances sealing capability, helping to reduce leaks. In precision applications, fine-thread stainless steel screws allow for more accurate control and adjustment.

However, fine threads also have drawbacks: their tensile strength and overall durability are lower than those of coarse threads, and the threads are more prone to damage. They are not recommended for applications requiring frequent disassembly. Additionally, the matching fasteners, such as nuts, must be manufactured to equally precise standards—any slight dimensional inaccuracy can easily lead to simultaneous failure of both the screw and the nut.

Fine threads are primarily used in metric pipe fittings within hydraulic systems, mechanical transmission components, thin-walled parts where strength is insufficient, internal mechanisms with space constraints, and shafts requiring high self-locking performance. To distinguish them from coarse threads, the pitch must always be specified in the designation of fine threads.

| Thread Standard Pitch Table | |||||||

| Nominal diameter | Tooth pitch mm | Nominal diameter | Diameter size | Pitch = number of teeth per inch | |||

| mm | Coarse teeth | Fine teeth | < 1/4" | in | mm | Coarse teeth UNC | Fine teeth UNF |

| M1 | 0.25 | 0.2 | 0# | 0.06 | 1.524 | — | 80 |

| M1.2 | 0.25 | 0.2 | 1# | 0.073 | 1.854 | 64 | 72 |

| M1.6 | 0.35 | 0.2 | 2# | 0.086 | 2.184 | 56 | 64 |

| M2 | 0.4 | 0.25 | 3# | 0.099 | 2.515 | 48 | 56 |

| M2.5 | 0.45 | 0.35 | 4# | 0.112 | 2.845 | 40 | 48 |

| M3 | 0.5 | 0.35 | 4# | 0.125 | 3.175 | 40 | 44 |

| M4 | 0.7 | 0.5 | 6# | 0.138 | 3.505 | 32 | 40 |

| M5 | 0.8 | 0.5 | 8# | 0.164 | 4.166 | 32 | 36 |

| M6 | 1 | 0.75 | 10# | 0.19 | 4.826 | 24 | 32 |

| M8 | 1.25 | 1 | 12# | 0.216 | 5.486 | 24 | 28 |

| M10 | 1.5 | 1.25 | 1/4" | 0.25 | 6.350 | 20 | 28 |

| M12 | 1.75 | 1.25 | 5/16" | 0.3125 | 7.938 | 18 | 24 |

How to Choose Between Coarse and Fine Threads?

Both coarse and fine thread screws are primarily used for fastening purposes.

Fine-thread screws are typically employed for fastening thin-walled components and parts with high anti-vibration requirements. The finer pitch provides superior self-locking performance, which translates to greater resistance to vibration-induced loosening. However, because the thread depth is shallower, fine threads have a lower tensile strength and can withstand less pulling force than coarse threads.

Without additional anti-loosening measures, fine threads generally provide better resistance to loosening compared to coarse threads. This makes them suitable for thin-walled parts and applications where vibration resistance is critical.

For adjustment applications, fine threads offer a distinct advantage due to their finer pitch. A notable limitation is that fine threads are not well-suited for use in materials with a coarse grain structure or low strength, as they are prone to thread stripping when subjected to excessive tightening torque.